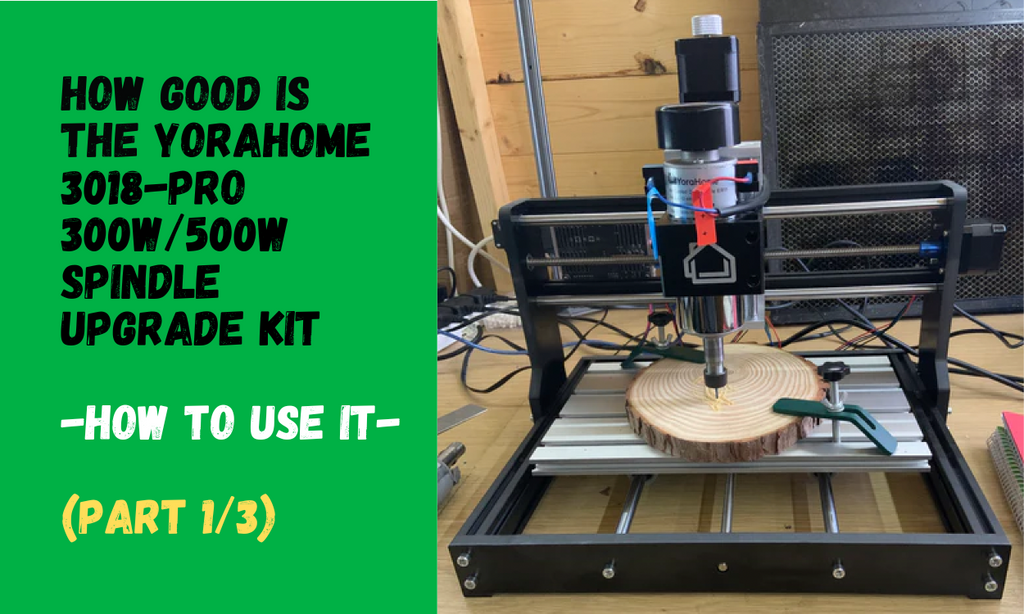

How Good Is The YoraHome 3018-Pro 300W/500W Spindle Upgrade (How To Use It)

Let’s get a CNC machine!

That was the start of the conversation about 3 years ago – my response at the time was “Get a what?”

My ever patient, (hahahaha) partner Shaun explained that it was a machine that would follow instructions sent from software to carve, etch, or use a laser to make decorative or useful items and this would be a good side-hustle for him/us.

Not completely convinced at that point, I started some research on various options available. After looking at different machines, I came across the YoraHome CNC Router 3018-Pro.

Well, having built the machine, Shaun then asked me try out the software to see what it could do, that was the last time he got to touch it!

As time has gone by, I’ve extended my original machine with the YoraHome 3018-Pro Expansion Kit (30x36cm) to increase the working area.

But like many people, I am not blessed with an enormous amount of space for my machines.

And to be honest, the biggest things I tend to do are cutting boards, so I don’t need a massive work area on the machine. So, the original set up of an open working area of 30x18cm (12x7") with an effective engraving depth of up to 4.5cm (1.8"). It is perfect, without taking up too much room.

I am lucky enough to have a YoraHome Mandrill CNC Router 3036 and a YoraHome SilverBack Benchtop CNC Router 6060 which are both big powerful machines and when I say big, the Silverback is huge with a working area of 60x60cm. (It’s too big for the space I have available really).

So, bigger isn’t always better. However, the bigger machines do have one great advantage, more powerful spindles.

The YoraHome CNC Router 3018-Pro comes as standard with a 775 Spindle Motor. The spindle motor is what drives the carving process, and its speed and power determine what materials can be cut – and how long a job will take.

Finding out that there was a YoraHome Spindle Upgrade Kit For 3018-Pro (All-In-One Package) which is an air-cooled 300W or 500W spindle for the 3018-Pro, was just too tempting not to try.

What are the differences between a 775 spindle and the 300W or 500W air-cooled spindle?

The air-cooled Spindle is much larger, so the new spindle needs a different Z assembly.

It is heavier as well, so it needs a stronger X-Axis lead screw.

The increased power of the air-cooled Spindle requires an independent power supply.

As the name suggests, the air-cooled CNC spindle makes use of a fan that emits air, which functions as a fluid to dissipate heat, reducing the chance of over-heating of the motor.

The air-cooled spindle has a manual speed control, to adjust spindle speed during a job.

It is much quieter than the 775 Spindle.

It has an increased RPM compared to the 775. The cutting speed is proportional to the spindle speed and the diameter at which cutting is being done. Put very basically the more power you have, the faster you can cut.

For those of us not blessed with huge amounts of patience either, this is a huge bonus.

How do you swap to an air-cooled spindle?

The instructions that come with the upgrade are excellent, along with the assembly video, make assembling the new set up simple.

Having dismantled the left hand-side of the machine and removed the original spindle assembly, you simply start the re-build, replacing the old spindle assembly. Installing the X-Axis screw is made easier when you start with the assembly flat on a table as per the picture below.

Once the screw is sit, the assembly is ready to put in place.

Sliding the assembly back into place, remember to tighten the set screws on the coupler.

To re-install the side plate bolts, its easier to put them in place first before offering it up to the machine body.

Once in place, with the x-axis screw and the gantry rods in the side panel, you can then tighten up the bolts on the left-hand side of the machine.

The wiring harness is then connected to the Control Box.

Then to the spindle itself.

In my excitement to try this out, I grabbed the first clamps that came to hand – these are from my Silverback, so I clamped down the piece of wood.

The next step is to connect to software, using Easel set it up as a new machine, with Manual Control for the spindle.

The software will guide you through checking the axis’ all work correctly and turning the control knob on the control box will adjust the spindle speed.

The 3018-Pro with 500 w Air-Cooled Spindle is now ready to be put through its paces.

Conclusion

First impressions, my gosh this is so quiet and wow that’s fast!!!

This is what I love about YoraHome, the 3018-Pro has been the standard CNC machine against which others have been measured, but not content with sitting on their laurels, they have pushed forwards with improvements and upgrades and continue to produce and support the best machines around.

I can’t wait to try this out “in anger” as they say. It seems the opportune moment to try Easel’s new 3D features, so look out for the next blog.

Get The Freshest Content

Straight To Your Inbox

Join over 3,000 creators who receive premium content, exclusive discounts, and all the must-know info on a weekly basis.