Bigger & Faster Projects!

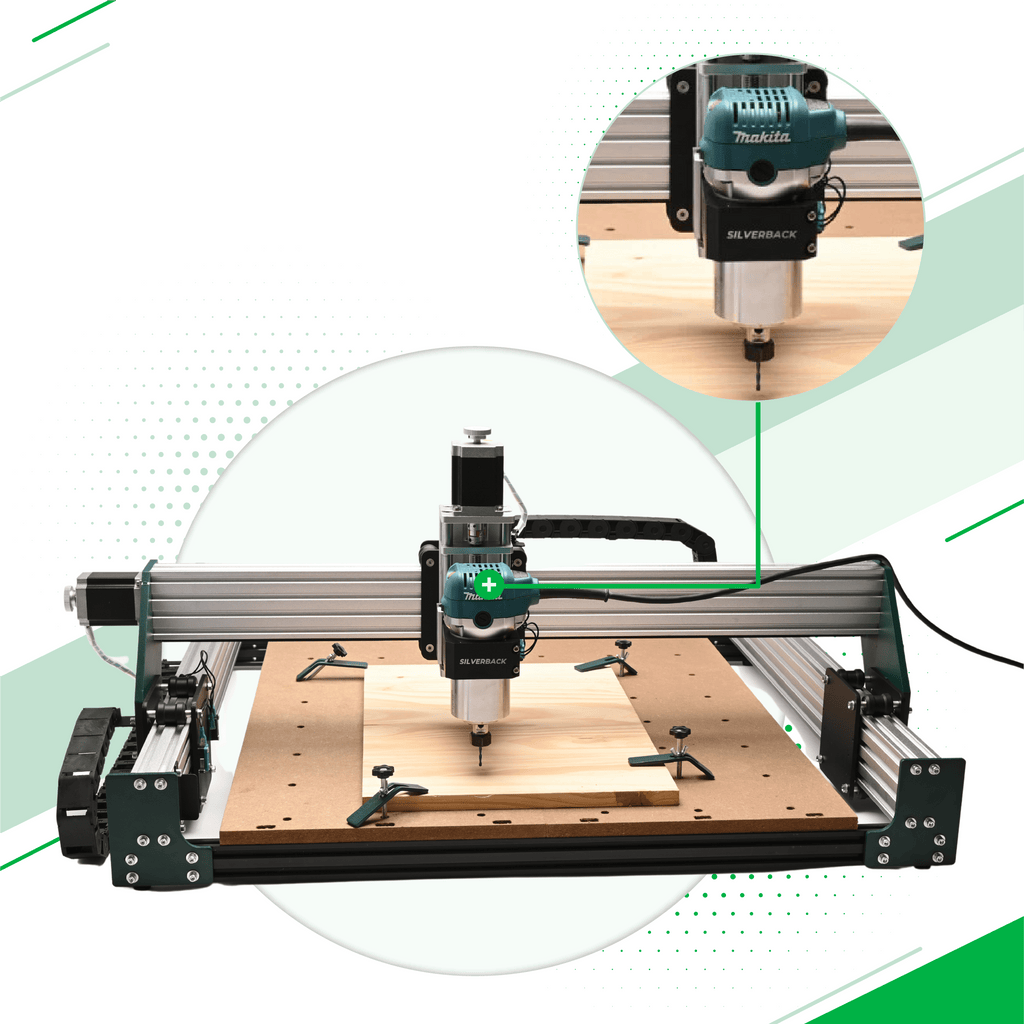

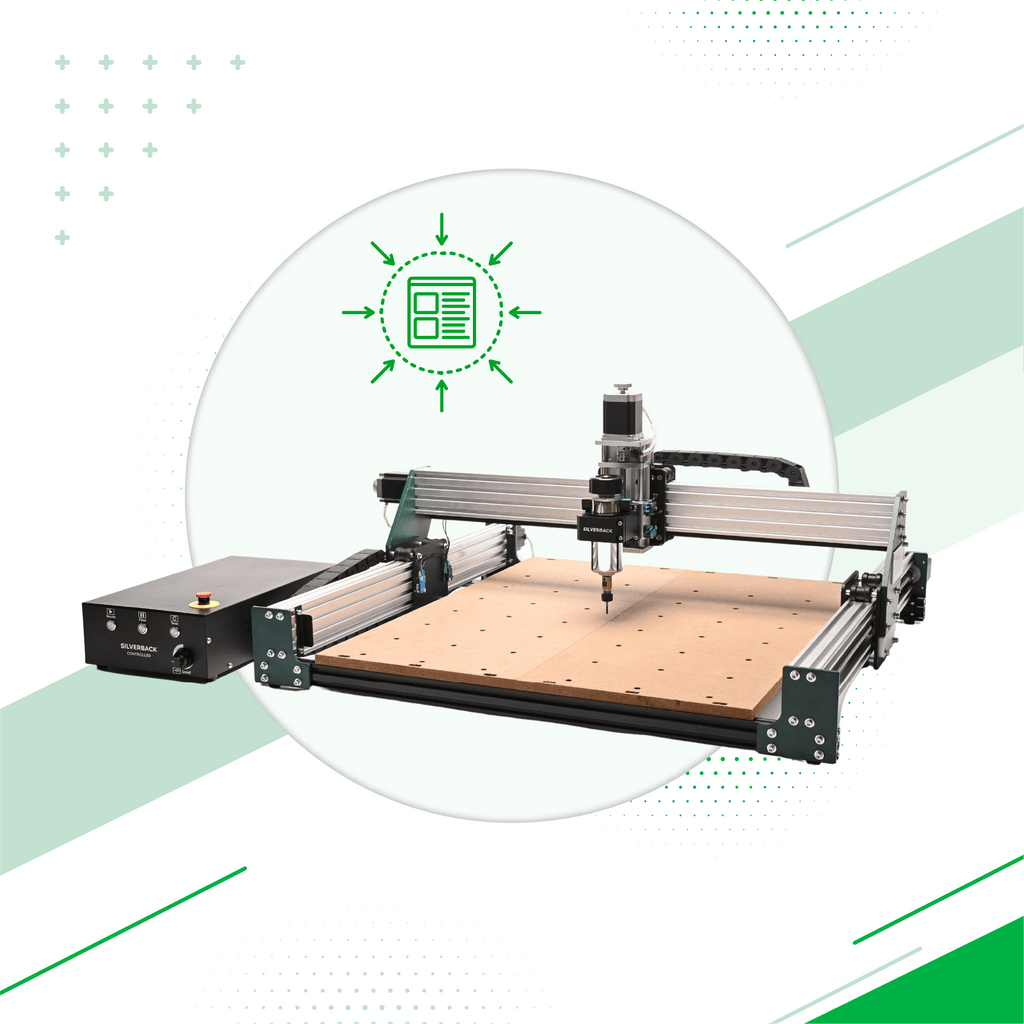

The SilverBack

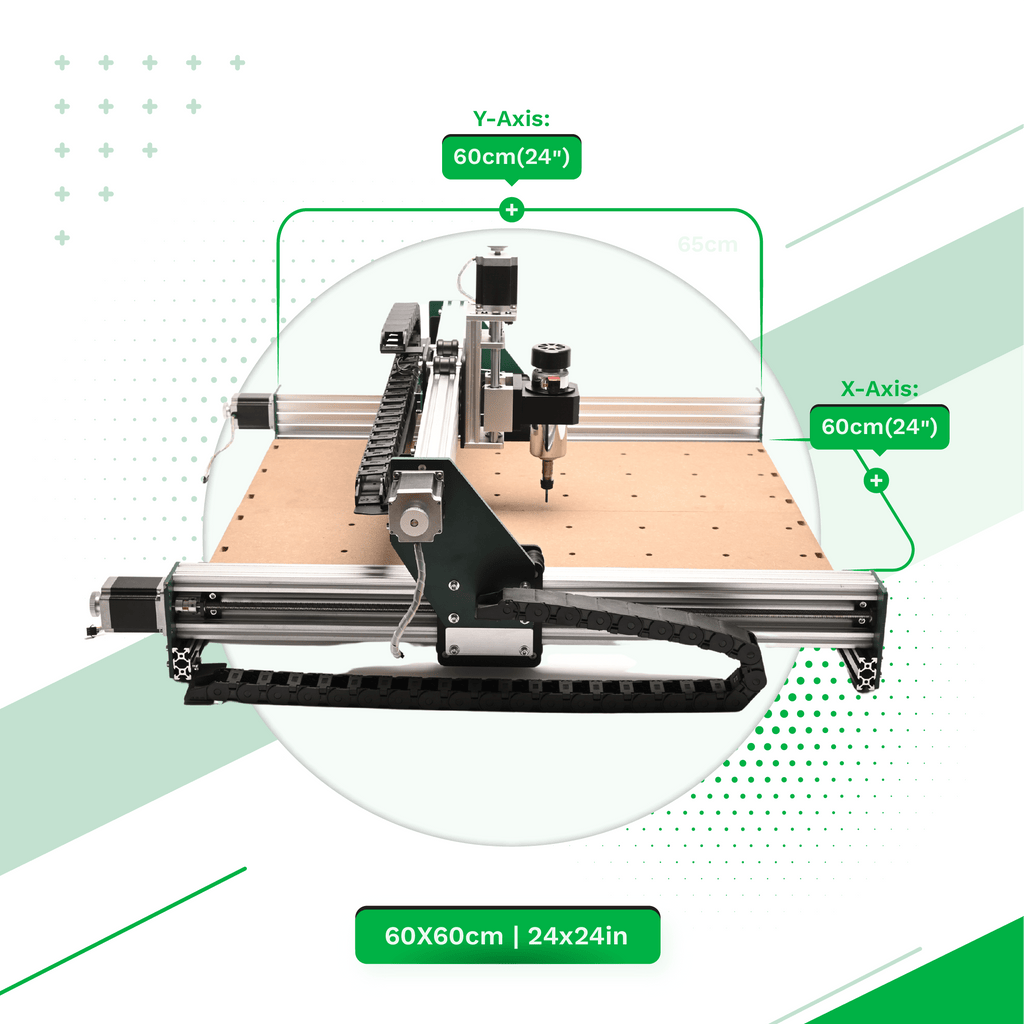

Very Large Working Area

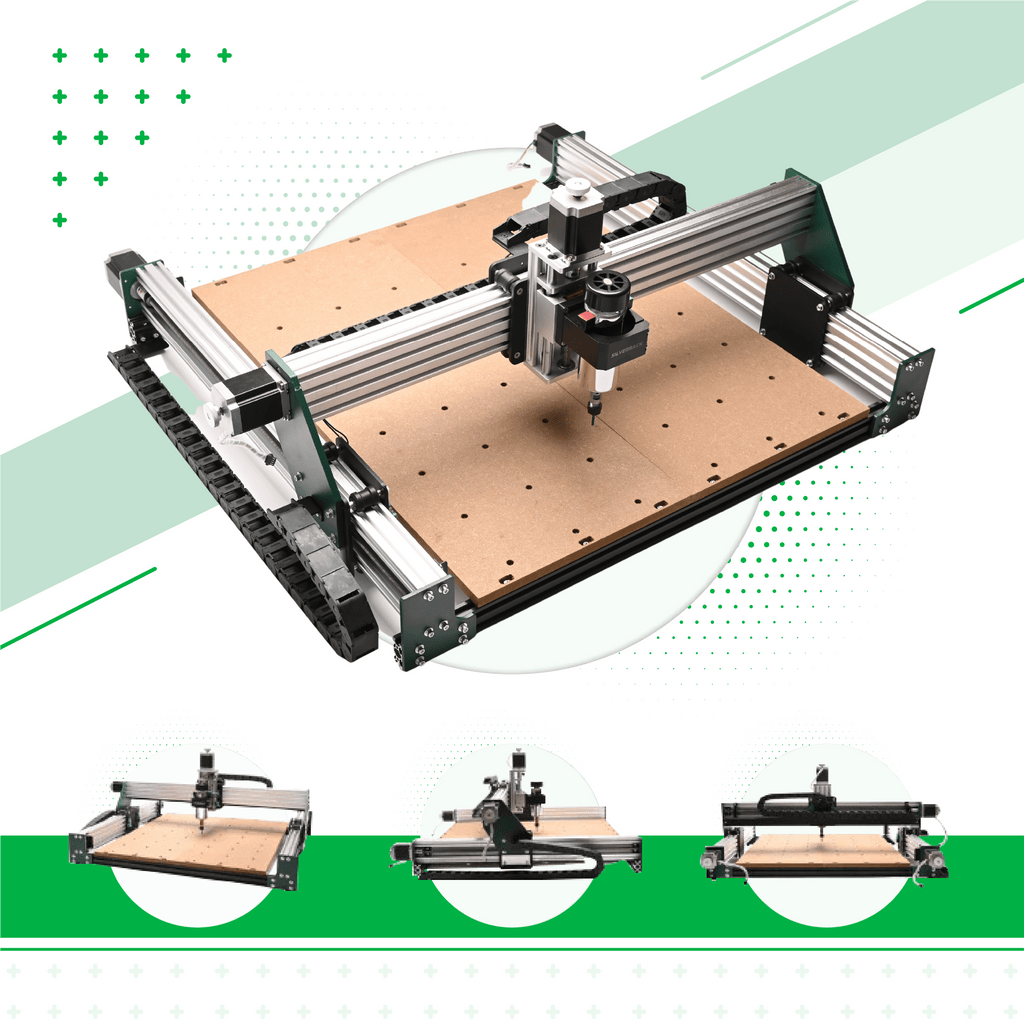

High Quality Aluminum Structure

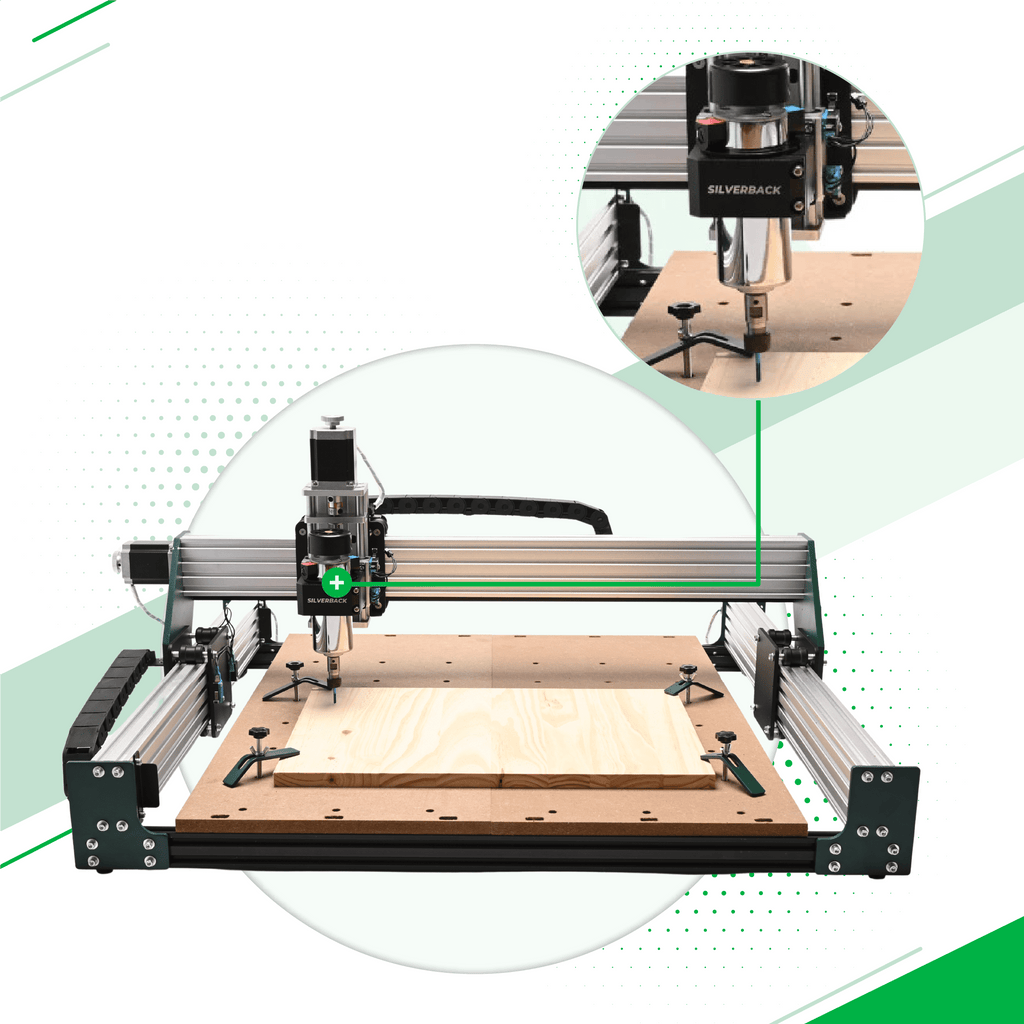

Powerful Spindle Motor Included

Compatible With Makita Routers

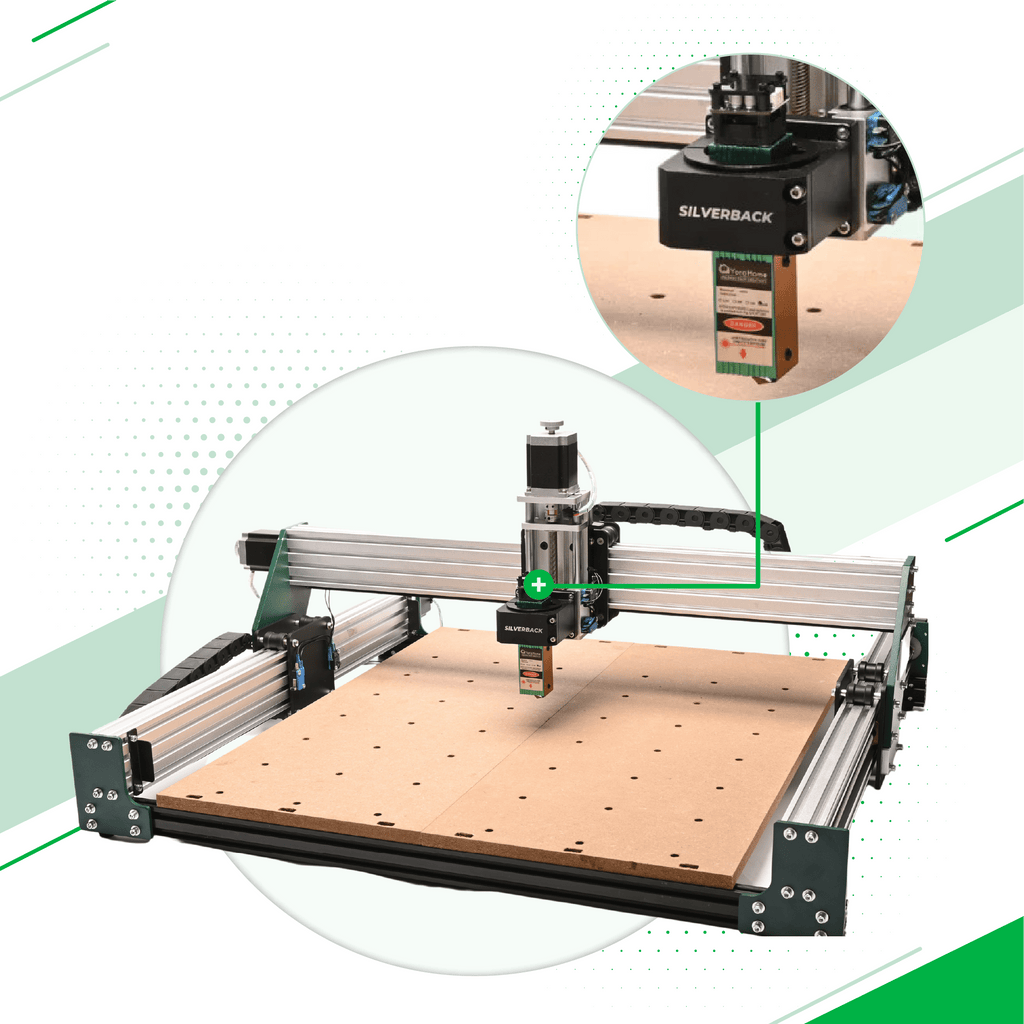

Compatible With Laser Modules

Excellent Performance

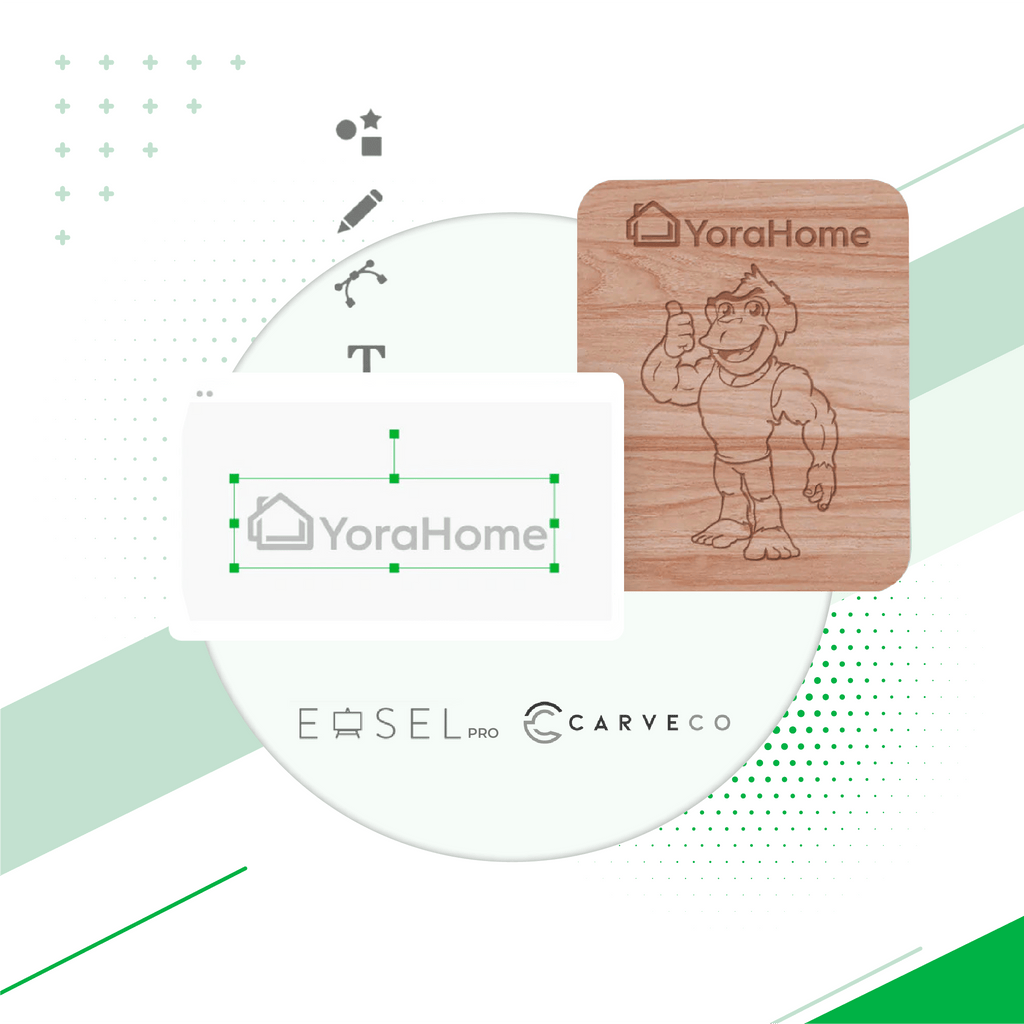

Compatible Software

Multiple Applications

Take Your CNC Game To The Next Level

Join The Amazing, Growing & Supportive YoraHome CNC Community!

Product Specifications

Frequently Asked Questions

-

How do CNC routers work?

CNC Routers use a spindle motor to turn a carving bit, allowing the user to carve out material to create designs of their choice.

The machine utilizes software on its computer to design and adjust the project, making the code necessary to operate the machine. The code is sent to the machine, and the workpiece and spindle are moved to allow the design to be carved.

-

What are CNC routers used for?

CNC Routers are commonly used for various projects, including signs, plaques, 3D carving, and similar items. Many users create exquisite projects and have done business out of custom creations.

-

What is the difference between CNC Router and a CNC mill?

A CNC Router is typically designed for softer materials such as wood, acrylic, and some stone substrates. The CNC Router is generally more portable and does not provide bit cooling.

A CNC Mill is a more industrial machine, most often used for shaping metals - as such, there is typically a liquid coolant to prevent the bit from overheating. This coolant system, combined with the large size of most milling machines, makes it prohibitive for the average home user.

-

Are CNC routers easy to use?

Yes! Our CNC Routers are designed for the home user or small business entrepreneur - easy to assemble and get started creating in a short time.

The software options available range from "beginner" level with Easel to "expert" level with the Carveco or Vectric software. Easel provides a very easy-to-use interface for a new user and is widely used within the small CNC world.

-

Can a CNC machine carve wood?

Yes! Our CNC Routers are designed for wood carving primarily - this is the most common use of CNC machines.

-

Can a CNC router cut metal?

Our 3018-Pro machine, the Mandrill and Silverback are capable of light carving on soft metals (certain aluminum alloys, brass, etc.).

Carving in metals will require appropriate bits, and a considerably slower engraving speed, to prevent overheating.

Our machines do not offer liquid cooling for the bits, a requirement for harder alloys.

-

Can a CNC machine engrave stone?

Our CNC Routers are capable of light engraving on some stone surfaces, such as slate - it does require the use of appropriate bits for the material, as well as limited depth. Significant carving of stone is not recommended on smaller CNC Routers.

-

What software does a CNC use? Is the software easy to use?

Several software packages are available for the CNC user - each offers various capabilities.

Our primary recommended software for beginners is Easel; this web-based software provides an easy-to-use interface and is very user-friendly. The Basic version of the software offers ample resources for the average user.

For more advanced users or those who want to get into 3D carving, slightly more advanced software is required to facilitate the tool paths needed. Two software packages that offer these capabilities are Carveco and Vectric. These programs require a bit of a learning curve, with many online resources available.

-

What is the difference between a CNC router and a laser cutter?

While there are many similarities, laser engravers and routers have some significant differences.

A CNC router will have a motorized Z axis and a spindle motor for operating router bits.

A laser cutter will typically not have a motorized Z axis and is not capable of operating a spindle motor or using router bits.

Please note that many of our CNC Router machines do have the capability to mount a diode laser module, allowing the machine to serve multiple purposes.

-

Is it worth buying a CNC router?

We certainly think so! A CNC Router can open up a multitude of creative possibilities for you to explore.

Making gifts for friends and family, carving custom projects for craft shows, or even starting a small business to sell your creations online.

-

What do I need to know before buying a CNC router?

The most crucial factor in purchasing a CNC Router is your intended usage. There are many power levels and work area sizes available in CNC Routers, so you will want to ensure that your machine will be able to engrave on the materials you wish to work with efficiently.Lower power spindles may not be capable of carving on all surfaces, so we advise planning for future growth, as we're sure you will enjoy your CNC Router and want to move on to larger projects.

Another critical factor in purchasing is the post-sales support offered - YoraHome provides multiple support options for our customers, and we want to ensure that you are successful with your new machine. Beware of sellers that don't offer support beyond an email "black hole"!

-

Why should I buy the YoraHome SilverBack CNC router 6060?

We understand there are many CNC Router options on the market - many of which will require additional accessories for optimum performance.

This is why we have worked to make the SilverBack the best deal on the market by including items that are usually added for extra cost:

- Heavy duty metal frame

- Powerful lead screws for all axis - no belts that can slack or stretch

- Included 500W spindle motor, with the option to install a Makita RT0701C motor - many other machines do not include any spindle at all!

- Integrated spoilboard - no need to provide your board and fasten the frame to it.

- Drag chains for cable management

- And most important of all - a HUGE work area - the base SilverBack comes with a 60x60cm work area, while the expanded model offers a 1x1m work area - 39x39 inches!

- Our outstanding support service - via email, telephone, video conference, and more.

Our Unbeatable Guarantee

We are out developing new upgrades and some of the most unique products in the world – and we back it up with our unbeatable 40 Day Guarantee.

If you don’t have a happy experience, we will do whatever it takes to make sure you are 100% satisfied with your purchase. Feel free to contact us for any assistance you might need.

2 Year Warranty

YoraHome warrants its CO2 and Fiber Laser Engravers against defects in materials or workmanship for two (2) years from the original date of receipt.

CNC routers, diode laser engravers, drawing/writing robots, and 3D printers are warranted for one (1) year. More details here.

Our 5 Point Customer Promise

- FREE Replacement Guarantee

- FREE Shipping Worldwide

- Tracking Number For Every Order

- Safe Payments via Paypal or Credit Card. We also offer financing with Affirm, Sezzle and Afterpay.

- US&UK-Based Support And Service

World Class Customer Service

The support we offer is second to none – users rave about how we don’t rest until every issue is solved to their satisfaction.

We love our customers. We take care of each one of them.

We offer support via email, chat, phone, video conferencing, our rich knowledge base, and our excellent Facebook group and CNC forum.

This is a lot of fun. My wife set up the machine and was up and running in less than 2 hours. YoraHome machines and accessories are fantastic, and the support you get is beyond fantastic. We are very happy to be part of the YoraHome family.

Our Partners