Honeycomb Bed For Laser Engraver Cutter: Everything You Need To Know

Anyone who has read my previous blogs knows I am passionate about toys!

YoraHome has brought to the market some fantastic machines, and I'm delighted to say I have quite a few of them. I'm not boasting; just admitting my weaknesses.

But, and this is a big but, I had missed out on some of the new stuff and needed to put that right, so first up was a Honeycomb Bed for the 6550-Pro Laser Engraver.

I had wanted one for ages but never been able to justify to myself and my bank account why I needed one; this should show and explain why.

So, back to basics.

1. What is a Honeycomb Bed?

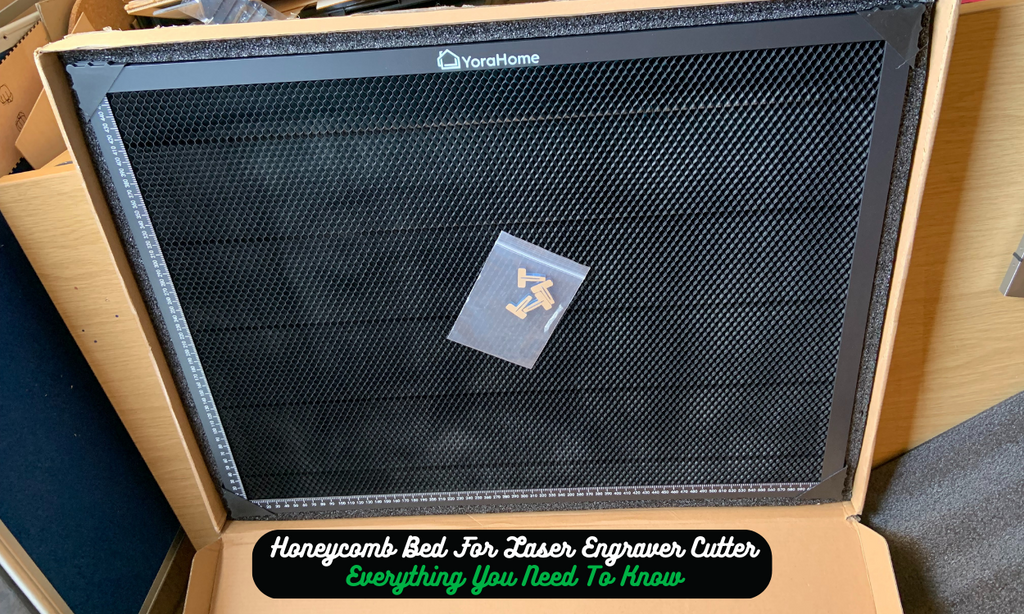

Here is mine, as I was getting it out of the box:

A honeycomb Bed is an alternative to the more common solid bed made from a sheet of solid metal.

It gets its name from the honeycomb-shaped cells enclosed within the frame. These cells allow for ventilation and air circulation.

I know I'm not the only one that has lifted my workpieces to examine them to find that the rear looks like someone poured syrup on it – that's due to the wood just sitting in its sap and air not circulating underneath.

It also comes with a solid steel plate to protect the surface underneath the machine to avoid any potential laser damage.

The Honeycomb Bed provides a level, stable surface for cutting the material, reducing the possibility of warping.

The YoraHome Honeycomb Platform also comes with acrylic pins to secure the material to the board.

The honeycomb structure dissipates heat more quickly, and the separate cells help prevent debris and smoke from accumulating, as both could affect cutting quality.

It also has a measuring scale on both the X and Y axis. You will notice the bed is not quite as big as the full bed size of the 6550-Pro. But, it will accommodate reasonably large size pieces of wood easily.

2. What are the Advantages of using A Honeycomb Bed?

2.1 Improved Cutting Quality

The cells distribute the weight of the material evenly and allow more accurate and consistent cuts, even when doing fine cuts like a mandala.

See how sharp and clean the cuts are:

2.2 Reduction in Material Waste

Through improved air circulation and ventilation, there is less errors and fewer requirements for re-cutting the pieces, as debris and smoke can drop from the material through the holes or be maintained in place under the workpiece without causing additional work for the laser.

2.3 Faster Cutting Speeds

The improved ventilation and circulation I keep mentioning also allow for faster cutting speeds, as the laser can operate at higher power without overheating in the same time frame as a solid bed.

They also reduce the time to cut and the requirement for as much patience, which will always be a winner for me.

3. How do you Maintain A Honeycomb Bed?

Taking care of a honeycomb bed involves maintenance and cleaning, as with all of the CNC machines and accessories.

Here are a few tips:

3.1 Regularly Inspect the Bed

Check for signs of damage or if any of the cells are clogged up with debris, as they could affect cutting quality and efficiency.

3.2 Cleaning

Use a soft brush or a vacuum to remove any loose bits from your previous cut, then wipe over with a damp cloth. No harsh chemicals are required. If there's some browning around the cells, use a baby wipe to clean it. And, allow drying to take place before using it again.

3.3 Storage

When not in use, store the bed next in a cool, dry place out of direct sunlight and moisture to avoid damage to the bed. Here is mine next to my machine:

Conclusion

Have I justified myself in getting a Honeycomb Bed for the 6550-Pro All-In-One System?

Well, let's say it was worth it for the increase in laser cutting speed.

But, with the clean and sharp cuts I'm now able to get too, right? I've justified it!

And I'm confident you can too.

Get The Freshest Content

Straight To Your Inbox

Join over 3,000 creators who receive premium content, exclusive discounts, and all the must-know info on a weekly basis.