Why Do I Want A 32-Bit Controller For My Laser?

So, you've probably seen that the new 6550-Pro Laser Engraver comes equipped with a 32-Bit controller - while the original 6550 Laser Engraver comes with a 8-Bit controller.

Now, we are happy to offer a 32-Bit Controller Board that is compatible with the original 6550 as well!

But you may be asking yourself "Why would I want to upgrade the controller, when my machine works just fine?" or "What is the 32-Bit board going to do for me, and why should I buy one?".

Hopefully, this article will help you answer those questions, and give you some insight into the advantages of the controller upgrade.

I. 8-Bit vs 32-Bit Controller

Obviously, the 32-Bit is a more powerful processor, and is capable of higher performance levels than an 8-Bit board.

It's not as straightforward as "well, math tells me it's 4 times better" - there's a lot more involved in the processor than just that simple increase.

8-Bit Controller

8-Bit controllers are limited by design to more simplistic mathematical operations - to get into "geek speak", they can only process as large a number as there are memory registers.

In the case of an 8=Bit controller, that is 2^8=256. This is why many older 8-Bit boards used a PWM laser control range of 0-255, as that's all the larger a number it can understand natively.

The 8-Bit controllers also typically are not able to efficiently calculate floating-point (decimal) numbers, so that is handled in a software overlay.

32-Bit controller

32-Bit controllers have a significantly larger number of memory registers; in this case, 2^32=4,294,967,296.

No more limitations on number calculations, and the board is able to run much more efficiently.

The floating-point number issue is also no longer a problem, so there is the ability to calculate with higher precision.

II. What does a 32-bit controller mean for your laser engraver?

Grey Scale (Dithering) capacity

8-Bit controllers have limited greyscale capacity; as it can only define 256 "shades" of grey.

The 32-Bit controller works with the software to effectively provide 65,536 "shades" of grey - so you'll get more defined scaling.

As an example, I downloaded this sample picture off the internet:

Fired up LightBurn, and imported the image - I did zero adjustments to the image before loading.

Used these settings:

Using one of the YoraHome 40W Laser Modules on a 6550, these are the results that I got - between the 8-Bit and 32-Bit boards:

As you can see; the 32-Bit board didn't burn as dark, and gives more shading in the background (as opposed to the dark "blob" in the upper right corner). I probably could have gotten better results with a bit more work - was aiming for just a quick "load and burn" example.

Movement Control

8-Bit controllers generally have to slow the movement for transitions, particularly around curves - this makes for longer project times.

32-Bit controllers can support speeds up to 8,000 mm/min; with higher acceleration levels. This allows the laser to move faster, with higher precision.

Noise

The 8-Bit controllers may experience some noise as they operate the stepper drivers, this is due to having to compensate for hardware limits by "step doubling", which causes the noise.

Since the 32-Bit controllers do not have this hardware limit, they can operate much quieter.

Memory Limits

Given the limits in an 8-Bit controller, the software tries to compensate in order to operate the machine as smoothly as possible. Since the GRBL firmware itself takes up almost the entire memory area, that doesn't leave a lot of room for buffering the job - so that can cause slowdown or hesitation.

The 32-Bit controller has greater memory capacity, so the processor can store upcoming processes in the buffer space - allowing the engraver to move smoother and reduce hesitation.

III. What are the other advantages of the 32-bit controller?

Large or complex designs

If you are doing large designs that require many lines of Gcode (therefore the .gcode file is large) then the 32-bit board is an advantage mostly for two reasons:

- More code can be read from the computer and loaded into memory to be put into the queue to be processed by the processor and converted into stepper motor commands and laser commands.

- The engraver can get more Gcode ready to be processed so that your engraver will never have to “pause” waiting for the processor to catch up.

Easy Installation

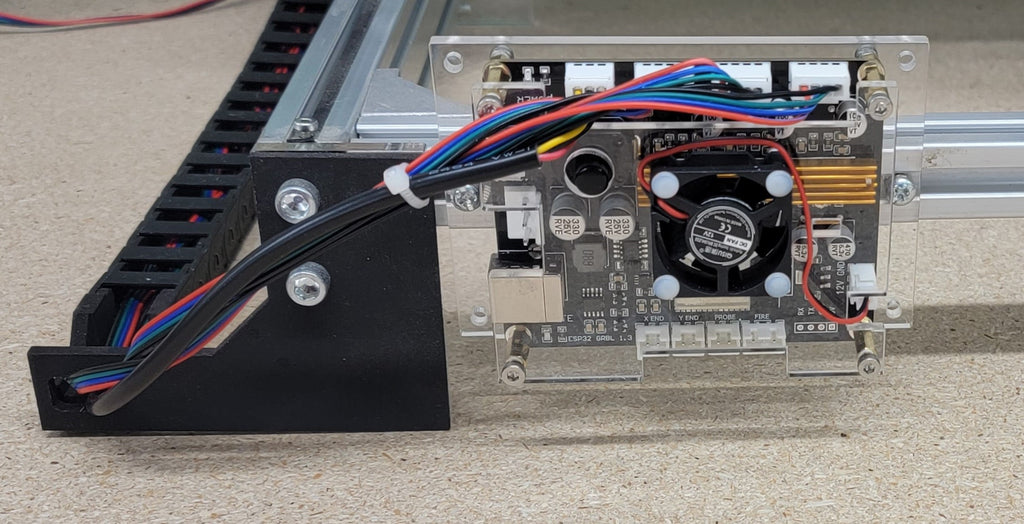

The 32-Bit controller is an easy install on your 6550:

- Unplug all harnesses from the 8-Bit board

- Remove 8-Bit board and mounting plate

- Assemble 32-Bit board mounting assembly

- Attach to the 6550 frame

- Reconnect all harnesses and start burning!

No interference with existing brackets or drag chain kits - board is slightly larger than the 8-Bit board in width. Note that the 32-Bit board also now includes a cooling fan for the stepper drivers - another improvement to increase longevity.

Additional Features

Finally, the 32-Bit controller provides room for many more future upgrade possibilities:

- Limit switches on a per-axis basis

- Support for multiple motors per axis

- Future boards may be able to control as many as 6 separate axes - while this is not as prevalent in laser engraving; it means future CNC Carving machines will benefit as well.

Hopefully, this has helped "decipher" some of the mystery around the different controller boards available - if you have any other questions about any of our products, please email us at support@yorahome.com.

Get The Freshest Content

Straight To Your Inbox

Join over 3,000 creators who receive premium content, exclusive discounts, and all the must-know info on a weekly basis.