Curious About 3D Printers? Read More, You Will Want One!

Have you ever been curious about 3D printing?

If you are anything like me, until recently the only thing that I knew about 3D printing was from watching Grey’s Anatomy where they manufactured a heart valve.

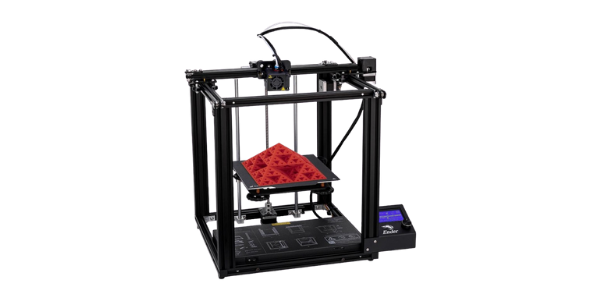

Well hopefully, this article will help you understand not only what 3D printing is, but also introduce you to the models of printers that YoraHome sells and showcase some of the things that you can do once you purchase your own Ender to unleash your creativity.

1. What is 3D printing?

3D printing, otherwise known as additive manufacturing, is a process of making a three dimensional solid object from a digital file by “drawing” the object one layer at a time using a variety of materials, but the most common is a melt able plastic filament called PLA (Polylactic Acid).

This process is accomplished by starting with a blueprint of the object you want to create. This model is then “sliced” into a series of 2-dimensional layers that each contain coded instructions that tells the machine what path the extruder needs to follow and how much material it needs to deposit as it follows that path.

There are several types of 3D printers, but the type we use and are going to focus on is the FDM (fused deposition modeling) type.

2. Basics Principles of 3D printing

The first step in the 3D printing process is the creation of either a .obj or a .stl file.

There are several sites where these can be downloaded for free such as Thingiverse, CGTrader, Myminifactory or GrabCad.

The creator also has the option of creating the file using a variety of modeling software options such as Blender, Tinkercad, Fusion 360, AutoCAD or Solidworks among others.

Once the creator has the file they want to use, the next step in the process is to slice the model into layers.

This is accomplished using software such as Cura, KISSSlicer, or Simplify3D. The slicing software breaks the model into layers of .gcode that act as instructions for the machine.

Some important tips to remember when printing include always making sure that the bed of the machine is clean and level before starting a print job.

We recommend wiping the bed with an alcohol wipe to remove any oils or debris from the bed. This will help ensure good adhesion of the first layer of material.

Another important step is making sure that the machine starts from the home position (x,y,z at zero).

Also make sure that the program that you are using to slice your model is compatible with your machine as some machines will only work with certain programs.

3. Why You Should Get A 3D Printer?

Other than the awesomeness factor of having the ability of creating a three-dimensional object from a spool of plastic (my first print, I was transfixed watching each layer be created), a 3D printer can be very useful in everyday life.

So far, we have created adjustable screw feet to hold the working platform for height adjustment.

For those with the early fixed focus lasers, we created an adjustable laser holder to set the height, and even custom chess sets for sale.

Since this Covid-19 madness has overtaken, our machines have been working around the clock on making medical supplies to help those fighting on the front lines.

Get The Freshest Content

Straight To Your Inbox

Join over 3,000 creators who receive premium content, exclusive discounts, and all the must-know info on a weekly basis.